Wind energy, aerospace and maritime fiberglass waste is no longer put to waste

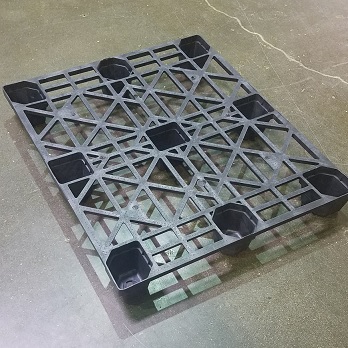

Global Fiberglass Solutions Inc. has a patented process for recycling fiberglass, grinding it into recyclable feedstock, and reusing the material in new products. This alternative creates an fully contained system rather than disposal in landfills or incineration.

There exists a widespread assumption that once a corporation uses its industrial fiberglass materials to capacity, the defunct items (for example, the blades of a wind turbine) must meet their end in a landfill. Also widely known is that landfills are filling up, dumping costs continue to rise, and we don’t stop needing fiberglass materials for modern industries. Global Fiberglass Solutions Inc. (GFSI), with its newest manufacturing plants in Texas and Iowa, proves the first assumption wrong and the second assumption newly irrelevant to companies hoping to bypass such issues.

As the icing on GFSI’s innovation cake, the company’s BladeTracker technology records the processing and manufacturing of materials digitally. This information proves itself invaluable to future manufacturing efforts as it enables the material to be recycled in infinite product life cycles after becoming a GFSI recycled product. GFSI, as a global company, works with business clients all over the world with major connections in Europe and Asia.