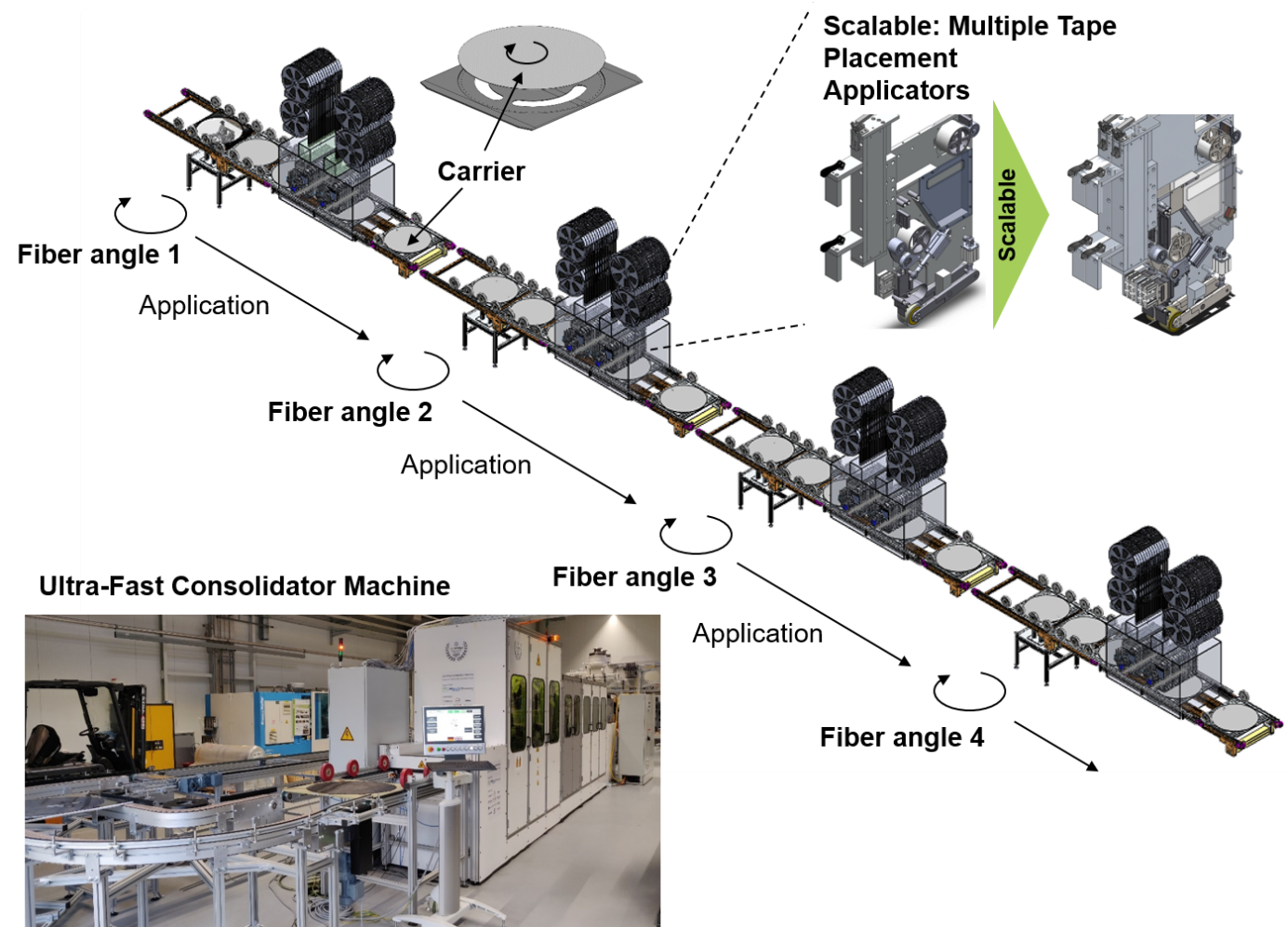

AZL’s ultra-fast consolidator machine for fast tape placement application

AZL’s Ultra-Fast Consolidator Machine offers many opportunities for individual tape projects on applications within industries like automotive (Car Center Tunnel, Door), aerospace (Bin Bracket) and for sports applications.

That composite tapes have a high potential for improving mechanical properties and reducing material as well as weight is not new. Many components from the automotive, aerospace, sports or leisure markets benefit from tapes. However, especially for many applications that need to be manufactured quickly and in large numbers, the integration of tapes remains a challenge.

The Ultra-Fast Consolidator Machine from AZL offers exactly a solution to this challenge. It pursues a novel manufacturing approach for laser-assisted automated tape placement. A central conveying system transports low-cost, low weight laminate carriers, feeding these through a production line of application stations, where tape is laid down by one or multiple parallel tape placement heads. Fibre angle orientation is flexibly set prior to tape placement. Using this system, fully consolidated thermoplastic tailored blanks can be produced in cycle times under 5 seconds.

|

The machine is available at the AZL for a variety of possible projects/applications. From individual testing of different tapes for ultra-fast placement, evaluation of the respective consolidation capability, sampling of tailored blanks to individual component development and analysis, e.g. with regard to the potential for back-injected tape blanks incl. prototype production – these are just some of the possibilities that are available. For injection moulding applications, 2 machines are also available at the AZL, including a table size of 2×2 m² for particularly large components.