Custom carbon windsurf fins

Sicomin’s latest marine collaboration with Sonntag Fins sees its industry leading GreenPoxy 33 bio-based epoxy resin used for custom carbon fiber windsurf fins – combining speed, fatigue performance and sustainability for some of the fastest sailors afloat.

With this in mind, Sonntag Fins approached Time Out Composite, Sicomin’s German distributor, looking for a new resin system that could reduce cycle times and improve manufacturing output. Bio-based systems were discussed, but the first product used by Sonntag was Sicomin’s SR1280 laminating system which delivered immediate results, enabling shorter cure cycles, and exceeding all of the previous mechanical test targets.

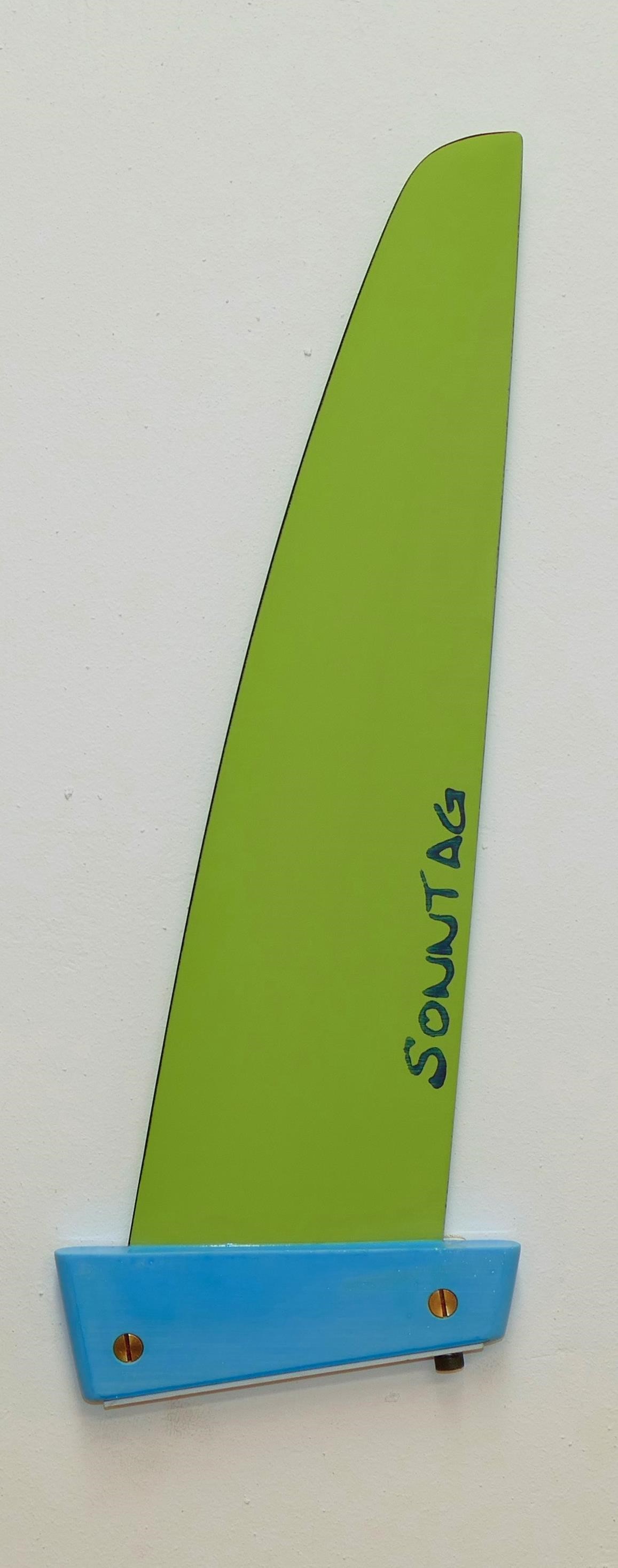

In 2020, Sonntag and Time Out Composite revisited the topic of a more sustainable epoxy resin system. It was the perfect time for Sonntag Fins, with their new unique bright green UV resistant outer finish, to go green on the inside too with Sicomin’s GreenPoxy 33 resin.

Test fins were produced with the new material performing well in production trials. Pure resin samples were also tested and post-cured at 140 ̊C, with the new GreenPoxy 33 samples showing significantly higher elongation at maximum resistance, meaning the cured epoxy was less brittle and susceptible to damage should a customer’s fin meet a rock. With mechanical properties improved, Sonntag switched production to GreenPoxy 33 in August 2020.

- The first step in the moulding process is the application of Sonntag’s green in-mold coating.

- Next, the individual fabric plies, cut using precisely machined templates, are placed into the mold and then wet-out with the low viscosity epoxy. With the laminate stack complete, the mold is closed and loaded into a heated press for around 2 hours to consolidate and cure the fin.

- After curing, the demolded fins are tempered in an oven at 140 ̊C, then only a light sanding is required to create the final surface roughness for optimum flow characteristics in the water.

- Finally, the fins are cut to the required length and the base adapter is molded to the epoxy-carbon blade in a specific mold.

With each fin being optimized for its rider, it is critical that each piece produced will bend and twist in exactly the way it has been designed to do so, providing the rider with exactly the feel and feedback they want for their board and fin. Each Sonntag fin is tested on a unique CNC controlled servo and stepper motor driven test bench that Joerg has developed, building a database of test results that not only ensures the products perform as designed but also validating the consistency of the manufacturing process and raw materials.

Joerg Sonntag, MD, Sonntag Fins commented:

“We produce high-performance windsurfing fins that need to accommodate significant loads during sailing. Fins need to combine flexibility with extremely high torsion stiffness that places high interlaminar shear forces on the resin, especially in our softer fins. A key requirement for us is a resin that maintains its mechanical properties for many years, and this is where the Sicomin systems deliver”