Frimo presents composites solutions for lightweight applications

Less is more when it comes to weight, material and energy consumption, cycle times and space requirements. Customers expect optimal production in terms of functionality, quality, process reliability, and efficiency. With cross-technology know-how and strong partnerships via the Composites Alliance with Schuler and Automotive Alliance with Hennecke, Frimo offers exactly that: unique solutions for lightweight and structural components that score high in terms of productivity and cost-effectiveness thanks to technology combination, function integration and automation.

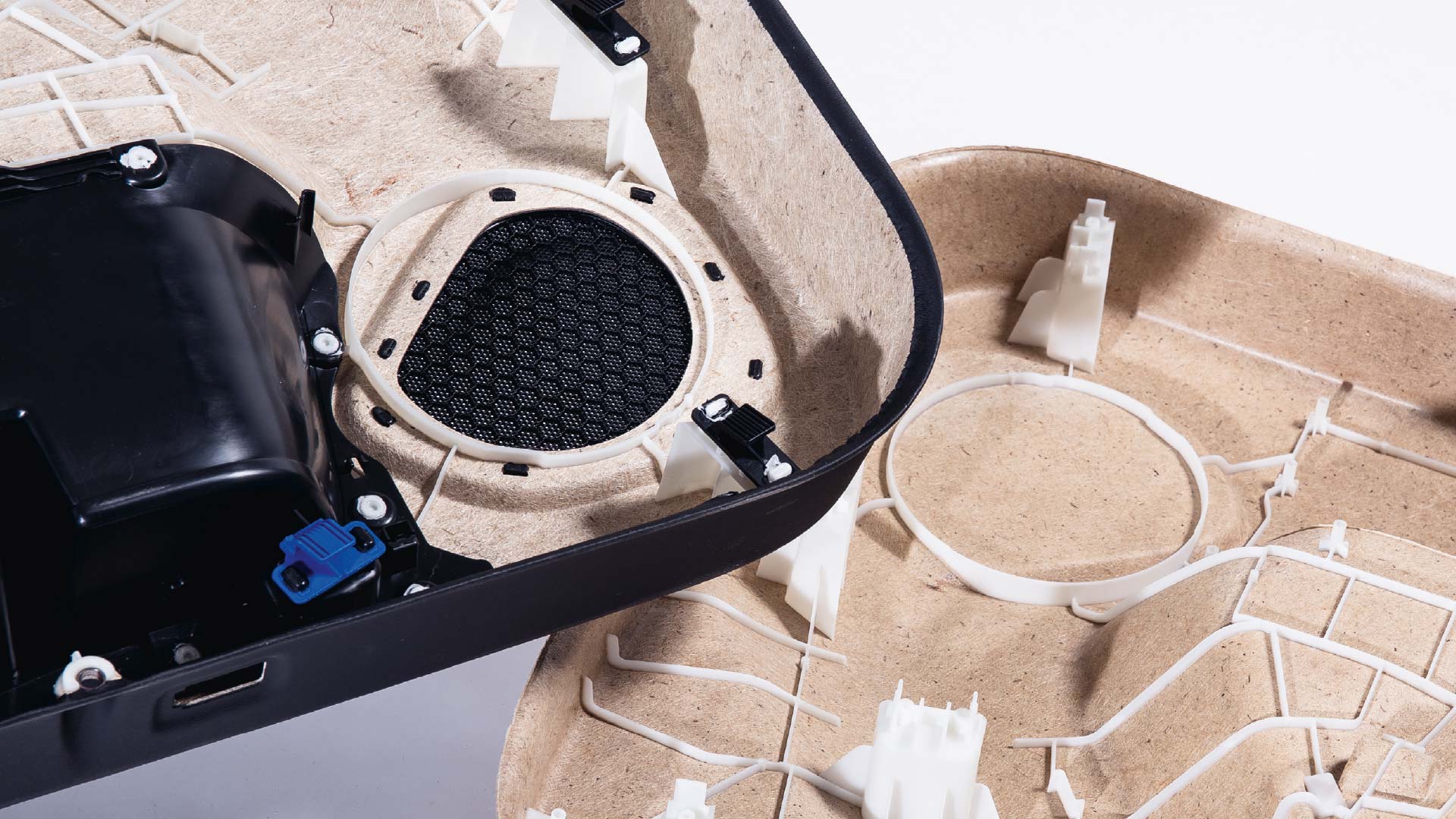

Frimo composites technologies include OSI (Organo Sheet Injection), NFPP Hybrid, and NFPP OneShot, preforming, RTM, wet compression molding, and a wide range of other forming processes. Frimo offers complete solutions for almost all thermoplastic and thermoset composites, covering the entire manufacturing process, from pre-forming and pre-cutting to molding, flexible cutting, joining and bonding, as well as component assembly and automation.

High lightweight potential for diverse process combinations; NFPP OneShot for single-stage process with decorative surface; NFPP Hybrid for added productivity with integrated functional elements

The Frimo Group understands sustainability as a holistic, entrepreneurial task, which is why they also pay attention to resource-saving handling and the lowest possible environmental impact when developing our products.

Fully automated processing of monolithic and sandwich components offer both cost and cycle time advantages through the use of faster resin systems

Light. Fast. Functional. Structural components made of continuous carbon, glass, or aramid fiber fabrics embedded in a thermoplastic matrix

Meet Frimo at JEC World 2022, hall 5, booth L80.